Behind Every Dissatisfaction is an Opportunity

- “As an engineer I’m constantly spotting problems and plotting how to solve them.” – James Dyson.

- “Your most unhappy customers are your greatest source of learning.” – Bill Gates.

If you are ever dissatisfied with a product or a service, you can be sure that there is an opportunity for a better product or service. If you are a marketer or a budding entrepreneur, always see if you are frustrated with a product or service that you are using; there could be a big opportunity that you may be able to unearth.

In 1979, English inventor James Dyson bought a Hoover Junior vacuum cleaner. He became frustrated with how it rapidly clogged and began to lose suction. He emptied the bag to try to restore suction but this had little effect. Dyson opened the bag and noticed a layer of dust inside, clogging the fine material mesh. The only way to get the vacuum cleaner working was to change the bag. That is when he decided that he would build a better vacuum cleaner.

During a visit to a local sawmill, Dyson noticed how it used a cyclone—a 30-foot high cone that spun dust out of the air by centrifugal force. He reasoned that a vacuum cleaner that could separate dust by cyclonic action and spin it out of the airstream would eliminate the need for both bag and filter.

Dyson developed a number of Dual Cyclone prototype designs between 1979 and 1984. The first prototype vacuum cleaner, the G-Force, was built in 1983, and appeared on the front cover of Design Magazine the same year. In 1986, a production version of the G-Force was first sold in Japan for the equivalent of £2,000.

In 1991, the Dyson vacuum cleaner won the International Design Fair prize in Japan, and became a status symbol there. And Dyson’s company was born. The Dyson vacs took the world by storm and soon all the other vacuum cleaner manufacturers were forced to follow his technology

Visual courtesy : https://www.flickr.com/photos/tnarik/

Dyson is a born inventor and innovator who has always looked at problems and found solutions that are better than the existing ones. In 1971, while working at his home, he found that he was having difficulties with his wheelbarrow – the wheel was sinking into the mud and would develop punctures and the steel body was heavy and unwieldy and prone to damaging the paintwork. He thought about the problem, developed a fibreglass body and used a ball instead of a wheel. The result was the ball barrow.

Visual courtesy : https://www.toolmonger.com

In 2009, Dyson’s company introduced the Dyson Air Multiplier. It is an electric fan that provides smoother airflow and, more importantly, has no exposed rotating blades. This made is much safer than conventional bladed fans. As described in Wikipedia, ‘the fan works by drawing 27 litres of air per second in through an inlet in the base pillar and forcing it through an outlet in the upper ring. The jet of air travels over the aerofoil shape of the ring, creating local low pressure, thereby pulling air from behind it as it decelerates in a process known as inducement, a property of Bernoulli’s principle. Once the air exits the ring it entrains the air in front and alongside, producing airflow of 405 l/second. Using this process, a small brushless impeller in the fan’s base can power a much larger air outlet without exposing any blades.’ A fan heater using the Air Multiplier technology followed.

Visual courtesy : https://www.flickr.com/photos/michaelaulia/

Earlier, in 2006, Dyson introduced the Dyson Airblade, an electric hand dryer. Instead of using a wide jet of heated air, it uses a layer of unheated air traveling at around 400 miles per hour. The Dyson Airblade could dry hands in 10 seconds and used less electricity than conventional hand dryers.

Visual courtesy : https://www.flickr.com/photos/bike/

In an interview to BBC, Dyson said, “My inspiration to invent and redesign is fed through frustration. I spend a lot of time taking things apart and putting them back together, considering how they work and how they might work better. Observation is important. The inspiration for incorporating a cyclone on a vacuum cleaner came from a visit to a sawmill. Using an industrial cyclone it was able to remove the sawdust from the air. I found myself thinking ‘Could we use this principle on a smaller scale?’ Five years later I had developed the G-Force, my first bagless vacuum cleaner.”

We marketers must learn from James Dyson. He and his band of engineers have shown that even the most common products that we take for granted can be bettered – substantially. We must all develop an inquisitive and questioning mind.

Source: Portions copied and adapted from Wikipedia.

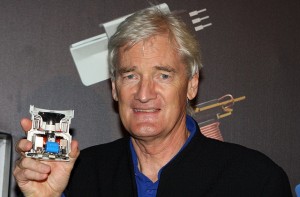

James Dyson Visual courtesy : https://www.flickr.com/photos/evarinaldiphotography/